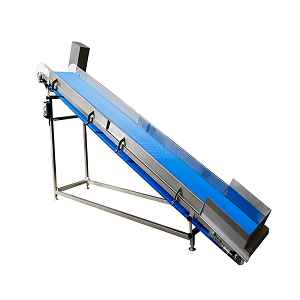

| Technical Parameters: | |

| Overall dimensions: | 2860×850×1500mm |

| Voltage: | 380V |

| Power: | 0.37kW |

| Production: | 800-1000kg/h |

| Customization: | customizable |

Vegetable Conveyor is a special equipment used for conveying, sorting, cleaning or processing vegetables and other agricultural products in the field of agriculture or food processing. Through conveying structures such as belts, chain plates, mesh belts, etc., vegetables are transported from one process to another, which improves production efficiency and reduces manual operations. It is suitable for a variety of crops such as root vegetables, leafy vegetables, and fruits.

Applications:

Vegetable primary processing line (cleaning, conveying before cutting)

Root crop transportation (such as potatoes and carrots)

Leafy vegetable picking and transportation (such as lettuce and spinach)

Fruit grading and transportation (such as apples and citrus)

Food central kitchen distribution system

Cold chain vegetable packaging line automation integrated equipment

Material

Frame material: mostly 304 stainless steel, with good corrosion resistance, often used for parts in contact with water and vegetables.

Conveyor belt material: PVC, PU, PP modular chain plate, stainless steel mesh belt, depending on temperature, load, and vegetable type.

Support structure: Aluminum alloy profiles or stainless steel square tubes are used for stable structure.

Motor and control part: Waterproof and dustproof motors are selected, often equipped with frequency converters and emergency stop switches to ensure safe operation.

Features:

Multiple conveying modes are available: Common forms include PVC belt conveyor, 304 stainless steel mesh belt conveyor, modular chain conveyor, etc., which can be flexibly configured according to the type of vegetables and process requirements such as cleaning and cutting.

Adjustable conveying speed: Generally equipped with a variable frequency speed regulation system with a speed regulation range of 0.5-10 m/min, which can adapt to different processing rhythms and process connections and improve the coordination of the entire line.

Structural modular design: The modular structure is easy to disassemble, maintain and clean, suitable for factory batch use, especially in cleaning lines, sorting lines and packaging lines.

Waterproof and anti-corrosion design: The whole machine often uses a 304 stainless steel frame, which is rust-proof and anti-corrosion, meets food-grade hygiene standards, and can adapt to humid or frequently cleaned environments.

Support multi-process integration: It can be integrated with cleaning machines, picking machines, air dryers, vegetable cutters, packaging machines and other equipment to form a complete set of automated vegetable processing lines.

Strong bearing capacity design: The belt width is mostly 300-1000mm, and the conveying weight capacity can reach 200-500kg/h, and even customized heavy-load transportation of more than 1 ton/h can be used.

Low energy consumption and silent operation: The motor power is commonly 0.37-1.5kW, the operating noise is ≤75dB, low power consumption and suitable for quiet working environments such as food processing workshops.

Advantages:

Improve processing efficiency and reduce labor costs: After using the conveyor, more than 60% of manual handling time can be saved. A 10-meter conveyor line can replace more than 5 manual operations, especially suitable for medium and large factory assembly lines.

Standardized operating procedures to reduce human errors: The conveying speed is uniform and stable, avoiding vegetable accumulation and omissions during manual operation, and improving production consistency and stability.

Improve food hygiene standards: The equipment uses food-grade materials (such as 304 stainless steel, PP food-grade belts, etc.), which are easy to rinse and sterilize at high temperature to prevent bacterial growth and meet the requirements of the HACCP system.

Adapt to various vegetable forms and states: Whether it is wet vegetables, root vegetables with mud, or large quantities of leafy vegetables, fruits, etc., different conveying methods and guide rail structures can be designed according to the form, with strong versatility.

Support customization and expansion upgrades: Different lengths (2-20 meters), widths (300-1000mm), height-adjustable legs, and turning devices can be selected according to different production lines to achieve flexible wiring.

Improve the overall factory automation level: Linked with automatic sorting, weighing, and visual inspection systems, fully automated closed-loop operations from feeding, processing, conveying, sorting to packaging are achieved.

Long equipment service life and low maintenance cost: The life of the belt or chain plate is generally 2-3 years, and the service life of the whole machine is more than 8 years. The maintenance is simple, and the annual maintenance cost is less than 1,000 yuan.

FAQ:

How long can the Vegetable Conveyor run continuously? Is it easy to get stuck?

Generally, the equipment supports 8-12 hours of continuous operation. If the anti-slip guide rail and tensioning device are selected, it is not easy to get stuck. The running time depends on the motor load and maintenance.

Does it support the transportation of high-humidity vegetables or washed vegetables?

Yes. Stainless steel mesh belts or perforated PVC belts can be selected, which have good drainage and are suitable for washing line and air-drying line operations.

Is it easy to clean? Does it support high-temperature disinfection?

The conveyor belt is detachable, the body is a seamless welded structure, and it supports water gun flushing. Some high-end models support high-temperature disinfection within 80°C.

Can the conveying speed be adjusted? How to adjust it?

Yes. Most models are equipped with a frequency converter, and the speed can be adjusted from 0.5 to 10 meters/minute by the knob to meet the linkage of equipment with different beats.

Can it be customized for turning or multi-layer conveying?

Fully supported. Functional modules such as turning, lifting, and flipping can be designed according to the site, and upper and lower layers of conveying can be supported to save space.