Parameters of meatball processing line:

| Name | Meat Grinder | Beater | Meatball forming machine | Water Tank |

| Model | DY-320 | DY-B110 | DY-550 | DY-4F |

| Voltage(v) | 380 | 380 | 380 | 380 |

| Power(kw) | 1.5 | 4 | 1.5 | 1.5 |

| Weight(kg) | 150 | 260 | 190 | 140 |

| Output(kg/h) | 500 | 15KG/pot | 90-500 | 500 |

| Body size(mm) | 900*500*900 | 1140*580*1310 | 900*510*1780 | 1480*480*680 |

| Material:304 Stainless Steel | ||||

| Can be customized according to needs | ||||

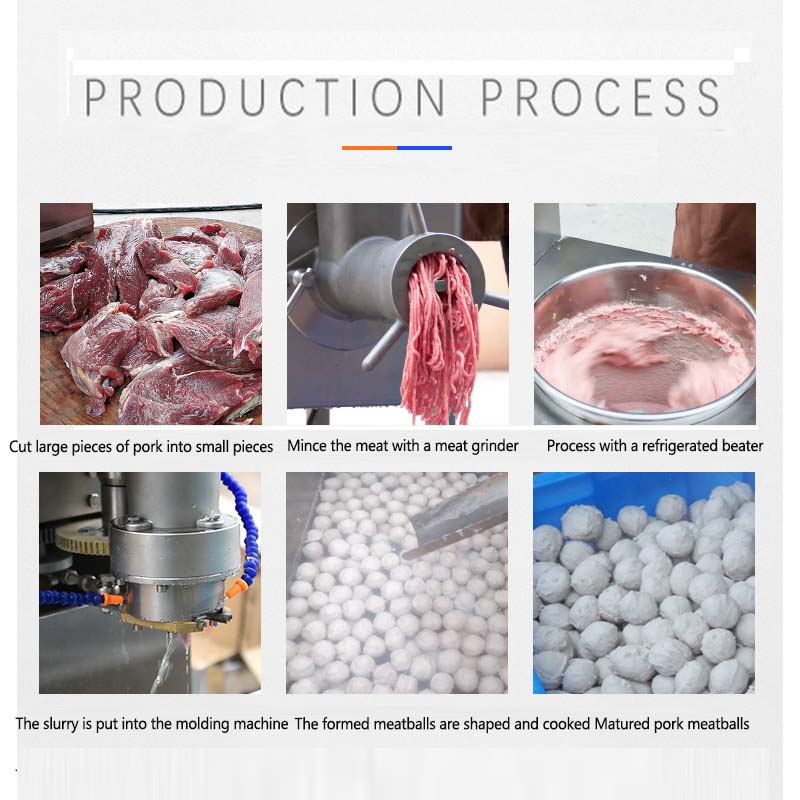

The following is a flow chart of the meatball processing production line:

The following is an introduction to each product:

Suitable for all kinds of fresh meat, meat processing plants, distribution centers, central kitchens, and large canteens. This vertical stainless steel powerful meat grinder uses a high-power pure copper motor, combined with a stainless steel body frame, a fine auger, stainless steel cross knife and round knife, which meets the needs of meat food processing and production.

Beater:

Compressor refrigeration slow meatball beater uses an advanced compression refrigeration system to refrigerate the outer barrel of the beater, effectively ensuring the quality of meat products during the beater process and preventing the temperature from changing the meat quality. In addition, during the beating process, the meat tissue cells can be reorganized by wire drawing, increasing the absorption of water and improving the tenderization of the meat. The slurry is made into meatballs, fish balls, etc., which are elastic, crisp, and chewy. Once the product is launched, it is deeply favored by meat product processing customers.

Meatball forming machine:

The dual-speed variable frequency meatball forming machine is the preferred forming equipment for producing various fish balls, vegetarian balls, pork balls, and tender and smooth meatballs. The forming effect is smooth, the outline is beautiful, and the specifications are uniform. It has high forming efficiency and stable performance.

Sink:

The automatic constant temperature shaping and maturing sink, also called the intelligent temperature control double heating sink, is a new design and development of our company. It is suitable for shaping and maturing heating sinks such as tribute balls, stuffed meatballs, lion heads, cuttlefish balls, solid meatballs, vegetable balls, and rice balls.

The meatball processing line can realize automated operation, which greatly improves the production efficiency of meatballs. Compared with manual production, the machine can produce a large number of meatballs in a short time and is suitable for large-scale production.The use of meatball making machines can significantly improve production efficiency and product quality, reduce labor and raw material waste, and ensure food hygiene and safety. It is an important tool for food processing companies to improve their competitiveness.

If you are interested in this, please contact me!!!