With the advancement of technology, the way of food processing has also changed. In recent years, this classic delicacy, meatballs, has gradually entered a new era of intelligent production. We often see beef balls in supermarkets and convenience stores. How are these meatballs made?

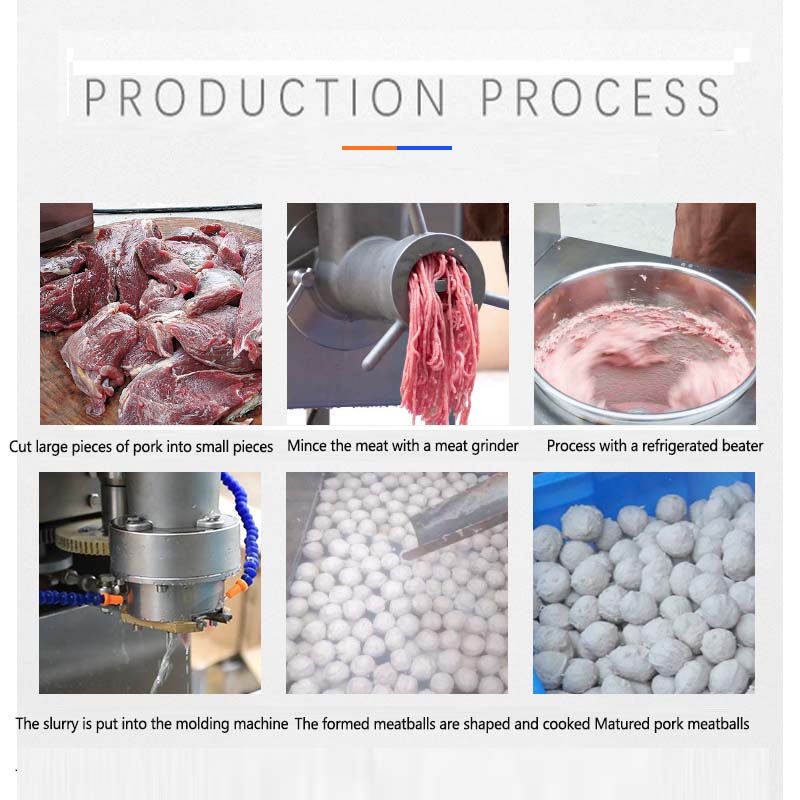

Meatball production process Line:

1. Raw material preparation

Choose meat: Choose meat suitable for making meatballs, such as pork, beef, chicken, fish, etc., to ensure the freshness of the meat.

2. Mixing and beating

Mincing: Use a Meat Grinder to grind the cut meat into minced meat. The fineness can be adjusted as needed.

Adding ingredients: Add salt, starch, egg white, chopped green onion and ginger, seasonings (such as soy sauce, pepper), etc. to the minced meat. You can also add auxiliary materials such as water, fish sauce, and chicken essence according to taste requirements.

Beating: Put the mixed minced meat and ingredients into a beater and stir them to fully blend the minced meat and ingredients to form a sticky meat paste. Pay attention to controlling the speed and time during the mixing process to avoid excessive mixing.

3. Molding

Meatball molding: Put the mixed meat paste into the meatball machine, and the meatball machine automatically squeezes out the meat paste and molds it into round meatballs. The size of the molding can be adjusted according to the mold of the equipment.

Hand shaping (optional): If you don't use a meatball maker, you can also shape the meatballs by hand.

4. Precooking or boiling

Precooking (blanching): Put the formed meatballs into hot water and blanch them quickly to shape the surface. The water temperature is usually controlled at around 80-90 degrees Celsius. Cook until the surface of the meatballs turns white and floats up, then remove them.

Boiling: The precooked meatballs can be continued to be boiled in boiling water to ensure that the inside is fully cooked. The cooking time is adjusted according to the size and number of meatballs.

Meatball making machines offer a variety of benefits:

1.The meatball making machine can realize automated operation, which greatly improves the production efficiency of meatballs. Compared with manual production, the machine can produce a large number of meatballs in a short time and is suitable for large-scale production.

2. Ensure product consistency

Uniform forming: The meatball making machine can ensure that the size, shape and weight of each meatball are consistent, ensuring product standardization, which is very important for market sales and brand image. And has a stable taste: through standardized formulas and processing procedures, the machine can ensure that each batch of meatballs remains consistent in taste and texture, improving the quality of the product.

3. Save labor and costs

Reduce manual operations: Using a meatball making machine can significantly reduce reliance on labor and reduce labor costs, especially in labor-intensive production environments.

Reduce the scrap rate: The machine operates accurately, reducing errors or substandard products caused by manual operations, thereby reducing the scrap rate and raw material waste.

4. Improve food safety

Reduce food contamination: The automated operation of the meatball making machine reduces the number of manual contacts with ingredients, reduces the risk of food contamination during the production process, and ensures food hygiene.

Hygienic Design: Most meatball making machines use food-grade materials and designs, making them easy to clean and maintain, further improving food safety.

5. Adapt to mass production

Suitable for industrial production: The meatball making machine is very suitable for scenes such as food processing plants and catering supply chains that require large-scale production of meatballs, greatly improving production capacity and market supply capabilities.

Reduce operating costs: Through efficient production processes and low scrap rates, meatball making machines help companies reduce operating costs and improve overall profitability.

In general, the use of meatball making machines can significantly improve production efficiency and product quality, reduce labor and raw material waste, and ensure food hygiene and safety. It is an important tool for food processing companies to improve their competitiveness.