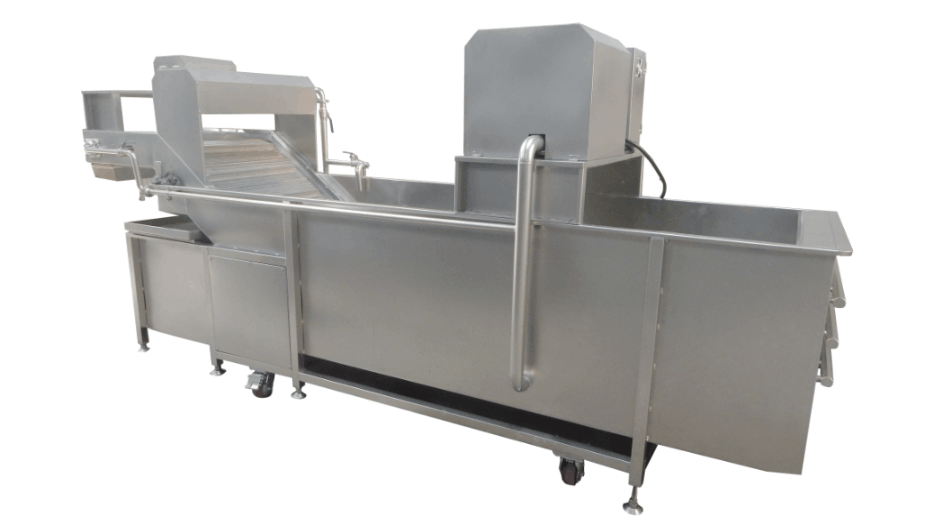

Bubble cleaning machines are widely used to clean various fruits and vegetables, such as apples, grapes, carrots, potatoes, etc. By generating a large number of bubbles and water flow, impurities such as dirt and pesticide residues on the surface of fruits and vegetables can be efficiently removed, while reducing damage to the surface of fruits and vegetables.Bubble cleaning machines can add ozone and slag removal functions, which can penetrate into the gaps of parts and remove pollutants such as oil, dust, etc.

| Technical Parameters: | |

| Overall dimensions: | 3500*1100*1680mm (customizable) |

| Voltage: | 380V |

| Power: | 4.5kW |

| Production: | 5800-1000kg/h |

Advantages

By generating bubbles and the force of bubble bursting, surface dirt, grease and other contaminants can be effectively removed to achieve efficient cleaning results.

Since bubble cleaning is a non-contact cleaning method, it can gently handle items of various materials and avoid damage to the surface of items caused by mechanical friction.

This cleaning method usually uses less water and detergent than traditional cleaning methods, and has environmental and economic advantages.

It is suitable for cleaning a variety of items, including tableware, glassware, electronic components, medical devices, etc., and is widely used in catering, medical, manufacturing and other industries.

The bursting of bubbles can penetrate into the gaps and tiny holes of items, effectively remove difficult-to-clean dirt, and ensure a thorough cleaning effect.

The automated bubble cleaning process reduces manual intervention and labor intensity, and improves cleaning efficiency and consistency.

The cleaned items usually dry faster, reducing drying time and waiting time, and improving production efficiency.

Since the cleaning process does not involve high temperature or strong brushing, the potential safety risks during operation are reduced.

The equipment design usually takes into account easy maintenance and cleaning, simplifies daily maintenance work, and ensures long-term stable operation of the equipment.

FAQ

What to do if the cleaning effect is not satisfactory?

Make sure that the bubble generator in the equipment is working properly and check whether the concentration of the cleaning fluid is appropriate. If the problem persists, check whether the filter needs to be replaced or cleaned, and whether there is a malfunction of the bubble generator.

What to do if the cleaning time is too long?

Make sure that the operating parameters of the bubble cleaning machine (such as bubble generation frequency, cleaning time setting) meet the cleaning requirements of the items. If the cleaning time is still too long, you may need to check the operating status of the equipment or adjust the formula of the cleaning fluid.

What to do if the equipment makes noise or vibration?

Check whether the bubble generator and other moving parts are operating normally. Noise or vibration may be caused by loose parts or unstable installation of the equipment. Tighten or adjust the equipment in time to solve the problem.

What to do if the foam of the cleaning fluid is unstable?

It may be that the concentration of the cleaning fluid is not appropriate or there is a problem with the bubble generator. Check and adjust the concentration of the cleaning fluid, and ensure that the bubble generator is in normal condition. Maintain or replace it if necessary.

What to do if there is water leakage during equipment operation?

Check whether all water pipe connection points and seals are intact and ensure that they are not loose or damaged. Leaks usually need to be repaired in time to prevent further damage to the equipment.

What if the items being cleaned are damaged?

Make sure that the operating parameters of the cleaning machine and the selection of cleaning fluids meet the material requirements of the items. Avoid using overly strong bubbles or unsuitable cleaning fluids to reduce potential damage to the items.

What if the equipment cannot start?

Check whether the power connection of the equipment is normal and make sure that there are no problems with the power switch and fuse. If the power supply is normal but the equipment still cannot start, you may need to contact a professional maintenance personnel to check for internal faults in the equipment.

What if the bubble generation is insufficient?

Check whether the bubble generator and related components are blocked or faulty. Clean and maintain the equipment regularly to ensure the normal operation of the bubble generation system.

What if the cleaning fluid is consumed too quickly?

Make sure that the amount of cleaning fluid used meets the requirements of the equipment and check for leaks or improper operation of the equipment. Optimizing the use and management of cleaning fluids can reduce unnecessary waste.