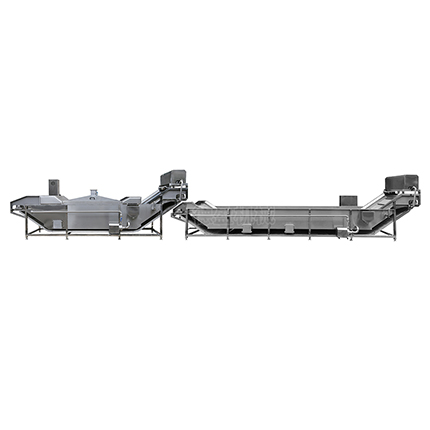

Uses: Blanching and cooling of vegetables, high temperature sterilization of the surface of materials.

Features: The blanching section completely immerses the materials in water to make the materials blanched evenly; the conveyor belts are all designed with scrapers, so that the blanching time of the materials in the water is basically the same; the whole line has continuity, uniform temperature, automatic temperature control; stepless speed regulation; small steam consumption, hot water circulation, steam and water mixing; mainly made of 304 stainless steel, strong and long service life.

| Technical Parameters: | |

| Overall dimensions: | 11000×1200×1500mm |

| Voltage: | 380V |

| Power: | 6.75kW |

Advantages of the Blanching and Cooling Line:

Uniform Blanching: The blanching section ensures that the material is completely submerged in water, providing consistent and uniform blanching for all products.

Efficient Conveyance: The conveyor belt is equipped with a scraper design, ensuring that the blanching time for materials in the water is almost the same, promoting efficiency and uniformity.

Continuous Operation: The entire line is designed for continuous operation, maintaining uniform temperature and automatic temperature control, which enhances productivity and quality.

Adjustable Speed: The line features stepless speed regulation, allowing for precise control of processing times and adaptability to different product requirements.

Low Steam Consumption: The system is designed to minimize steam consumption, utilizing hot water circulation and steam-water mixing to optimize energy usage.

Durable Construction: Made primarily from 304 stainless steel, the equipment is robust and has a long service life, ensuring reliable and durable performance.

Application Fields:

Vegetable Processing: Ideal for blanching and cooling various vegetables, ensuring they are uniformly processed and prepared for freezing, canning, or further processing.

Fruit Processing: Suitable for processing fruits that require blanching before further treatment, ensuring high quality and consistency.

Bulb Processing: Specifically effective for medium-sized bulbous plants, such as onions and garlic, ensuring thorough blanching and cooling.

Food Industry: Widely used in the food industry for preparing ingredients that require blanching as part of their processing workflow.

Catering and Meal Prep: Useful in large-scale catering and meal preparation operations where uniformity and consistency in blanching are crucial for product quality.

The Blanching and Cooling Line is a versatile and efficient solution in the machinery industry, offering significant advantages in terms of uniformity, energy efficiency, and durability, making it suitable for a wide range of applications in food processing and related industries.