The Vegetable Cube Cutting Machine. This state-of-the-art equipment is designed to transform the way vegetables are prepared and processed, offering unmatched precision and efficiency in the culinary world.

Features:

Efficient Cubing: The Vegetable Cube Cutting Machine employs advanced cutting technology to swiftly and precisely transform a variety of vegetables into uniform cubes. Its high productivity ensures large quantities of vegetables are diced quickly, enhancing kitchen efficiency.

Versatility and Adaptability:

This machine is incredibly versatile, accommodating a wide range of vegetables, from root vegetables like potatoes and carrots to softer ones like tomatoes and bell peppers. Its adaptability makes it suitable for various culinary applications, including salads, soups, stir-fries, and casseroles.

Precision and Consistency:

The machine guarantees consistent cube sizes, ensuring uniformity in dishes. Its precision cutting mechanism maintains the desired dimensions, enhancing the visual appeal of the prepared food and providing a professional touch to culinary presentations.

Photos after Dicing:

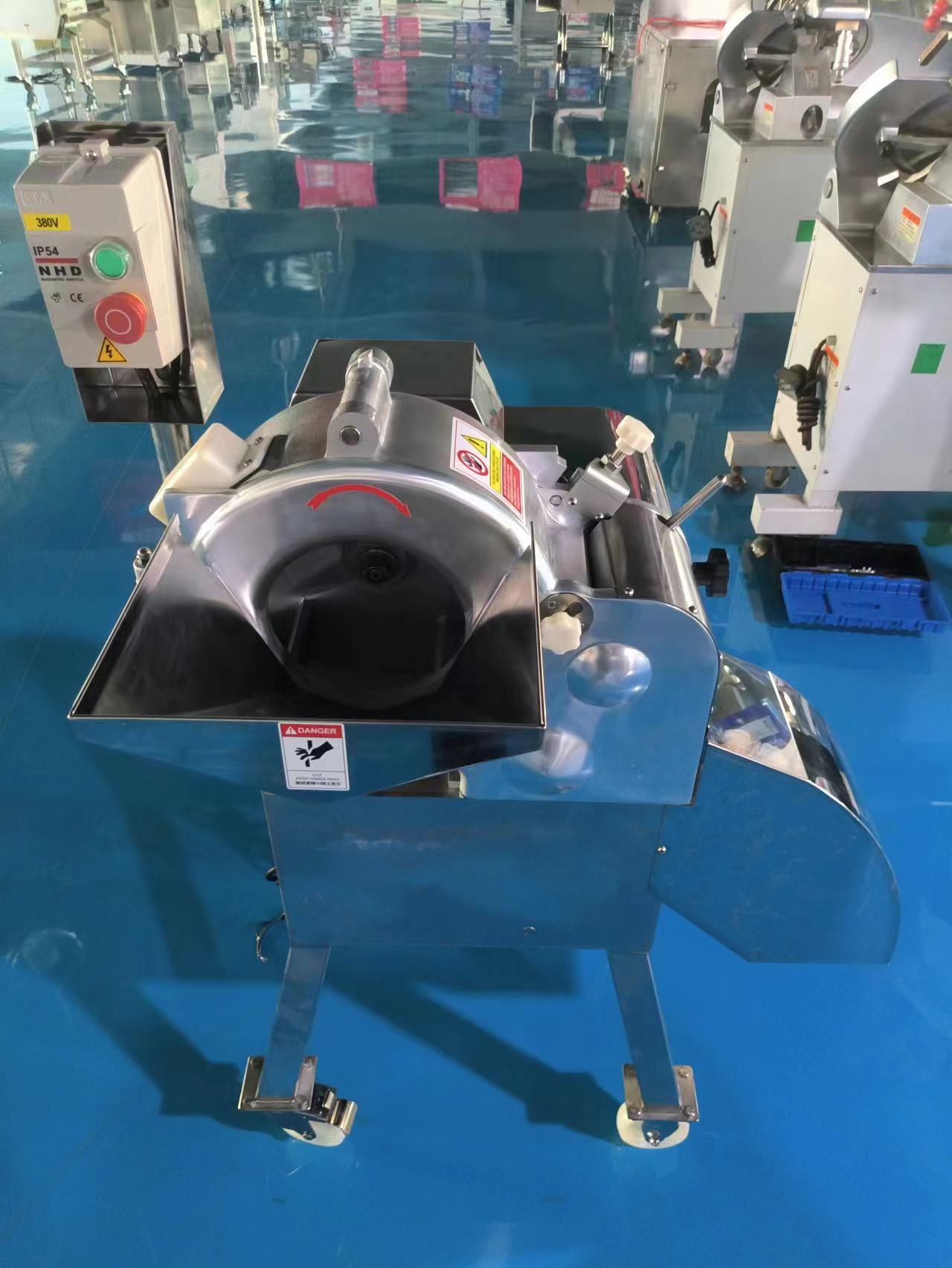

Dicer Real Shot Photos:

Uses:

Commercial Kitchens and Restaurants:

Ideal for high-volume food preparation, the Vegetable Cube Cutting Machine is a staple in commercial kitchens and restaurants. It expedites the cooking process, allowing chefs to focus on recipe creativity and overall kitchen management.

Food Processing Industries:

Food processing companies benefit significantly from this machine, as it streamlines the preparation of vegetables for various packaged food products. Its efficiency reduces labor costs and ensures standardized vegetable cuts for mass production.

Catering Services:

Caterers rely on this machine to handle large-scale events where precision and efficiency are paramount. From salads to appetizers, the machine ensures that dishes are prepared with consistent, visually appealing vegetable cubes, enhancing the overall catering experience.

Health Food Outlets:

Businesses specializing in health-conscious and fresh food offerings utilize the Vegetable Cube Cutting Machine to prepare ingredients for salads, wraps, and other nutritious meals. Its ability to cut vegetables uniformly enhances the presentation of health-focused dishes, attracting health-conscious customers.

In summary, the Vegetable Cube Cutting Machine's efficiency, adaptability, precision, and consistency make it indispensable in various culinary settings, ensuring uniform vegetable cubes for a wide array of dishes, from everyday meals to gourmet creations.

Q&A

Vegetable Cube Cutting Machines are versatile and can process a wide variety of vegetables. Common vegetables processed by these machines include potatoes, carrots, zucchini, bell peppers, onions, and tomatoes, among others. The machines can handle both root vegetables and softer vegetables, making them suitable for diverse culinary applications.

Yes, Vegetable Cube Cutting Machines are designed to handle large volumes of vegetables efficiently. These machines are engineered for high-speed operation and can process a significant quantity of vegetables within a short time. This capability makes them invaluable in commercial settings where large-scale food preparation is required, such as in restaurants, catering services, and food processing facilities.

Yes, Vegetable Cube Cutting Machines are designed with adjustable features that allow operators to customize the cube sizes. These machines come with interchangeable cutting grids and blades, enabling users to change the dimensions of the cubes produced. By selecting the appropriate cutting grids and adjusting the machine settings, operators can achieve various cube sizes, catering to different culinary requirements.

Vegetable Cube Cutting Machines are primarily designed for fresh vegetables. Using these machines for frozen vegetables may not yield optimal results. Frozen vegetables have a different texture and consistency compared to fresh ones, and the blades and cutting grids of the machine may not effectively handle the hardness of frozen produce.

Yes, Vegetable Cube Cutting Machines are designed with ease of cleaning and maintenance in mind. They often feature components that can be easily disassembled for thorough cleaning. Stainless steel, a common material used in these machines, is corrosion-resistant and can be cleaned and sanitized effectively, ensuring food safety.

Yes, Vegetable Cube Cutting Machines can be customized or equipped with specialized attachments to handle specific vegetable types. Manufacturers offer a range of cutting grids and blades tailored for different vegetables, accommodating their unique textures and shapes. For example, softer vegetables like tomatoes may require different cutting mechanisms than denser vegetables like potatoes.

Yes, Vegetable Cube Cutting Machines can handle delicate vegetables without crushing or damaging them. These machines are equipped with precision-engineered blades and cutting grids designed to make clean, sharp cuts without exerting excessive force. Delicate vegetables such as tomatoes, cucumbers, and mushrooms can be processed efficiently, producing uniform cubes without compromising their texture or appearance.

Yes, Vegetable Cube Cutting Machines can be seamlessly integrated into automated food processing lines. These machines are designed with interfaces and controls that allow them to communicate with other equipment in the production line. Integration enhances overall efficiency and reduces the need for manual intervention, enabling continuous, high-volume processing of cubed vegetables for various food products.

| Technical Parameters | |

| Overall dimensions | 1370×1110×1250mm |

| Voltage | 380V |

| Power | 1.5kW |

| Output | 1000-2000kg/h |

| Cutting size | 5-20mm optional, non-adjustable |

| Machine weight | 280kg |