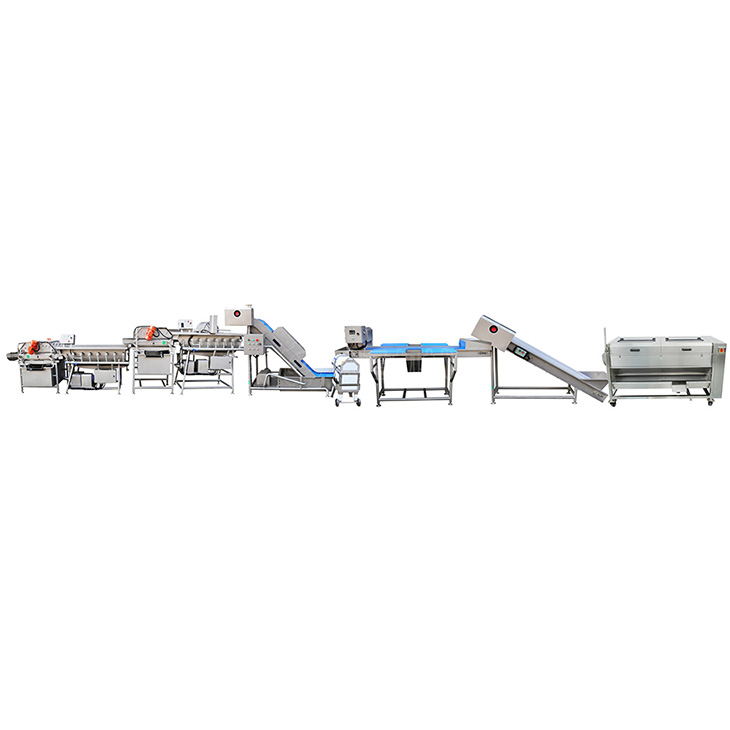

The bulb processing production line is mainly used for cleaning, peeling, cutting and cleaning of root vegetables. It consists of 7 equipments in total.

The order is: cleaning and peeling machine, conveying and dividing machine, shredder/slicer/dicer, pre-washing elevator, eddy current cleaning and disinfection machine. The whole line is reasonably designed and highly automated, and is an ideal processing equipment for clean vegetable processing and central kitchen.

| Technical Parameters: | |

| Overall dimensions: | 11500×1100×1400mm |

| Voltage: | 380V |

| Power: | 7.8kW |

| Machine weight: | 500-800kg/h |

Features

Comprehensive Processing Stages:

Washing and Peeling Machine: Removes dirt and peels the vegetables.

Conveying and Sorting Machine: Transports and sorts the vegetables for further processing.

Cutting Machine: Includes options for shredding, slicing, and dicing.

Pre-Washing Elevator: Elevates and pre-washes the vegetables.

Cyclone Cleaning and Disinfection Machine: Thoroughly cleans and disinfects the vegetables.

High Automation Level:

The production line is designed for high automation, minimizing manual labor and increasing productivity.

Ideal for Central Kitchens:

This processing line is well-suited for central kitchens and facilities that require high volumes of clean, prepared vegetables.

The Medium-Sized Bulbous Vegetable Processing Line can be used to process a variety of root and tuber vegetables, including but not limited to:

Potatoes/Carrots/Beets/Turnips/Radishes/Sweet Potatoe

This line is versatile and suitable for any bulbous or root vegetables that require washing, peeling, cutting, and cleaning.