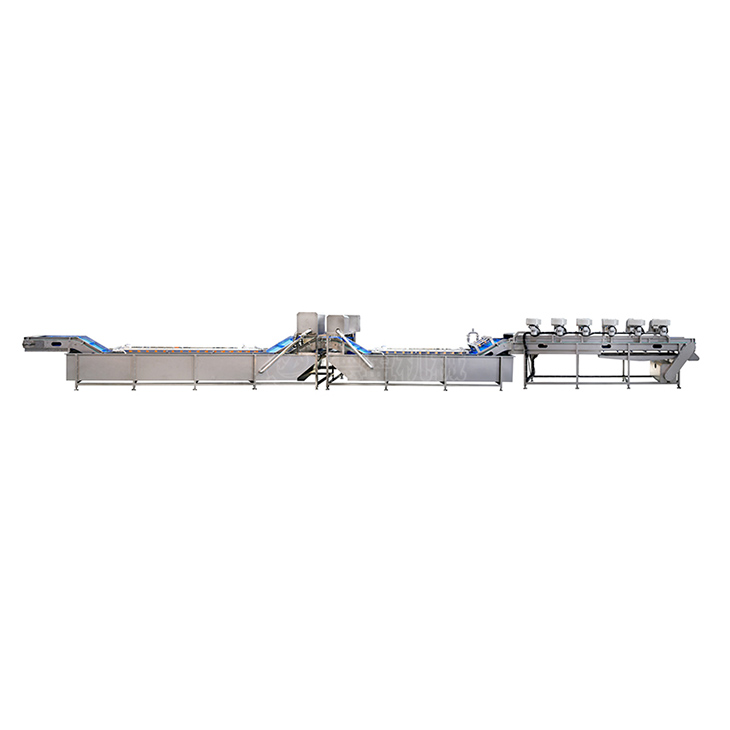

Vegetable Washing and Drying Line is used for washing vegetables such as spinach, water spinach, chives, leeks, and chives, and blowing off water droplets on the surface.

Features:

Use a fan to bubble clean water to make the materials roll and clean. There is a filter device in the water tank, and the water is recycled after filtering. The material is poured into the feed port and will move forward with the conveyor belt. In this process, the material is cleaned by surfing, bubbling, and spraying.

1. Jet-type vegetable washing machine (for initial washing in the front section, the feed port is 1 meter high);

2. Jet-type vegetable washing machine (for fine washing in the back section);

3. Wind-blown drying equipment (configured in the back section of the fine washing tank);

| Technical Parameters: | |

| Overall dimensions: | 14000(L)×1560(W)×1800(H)mm |

| Voltage: | 380V |

| Power: | 11.5kW |

| Machine weight: | 600-1000kg/h |

Advantages:

Effective Cleaning: Utilizes a combination of bubbling, surfing, and spraying to ensure that vegetables are thoroughly cleaned as they move along the conveyor belt.

Water Recycling: Equipped with a filtration system in the water tank, allowing the water to be filtered and reused, promoting water conservation and cost savings.

Consistent and Gentle Handling: The continuous movement of vegetables ensures consistent cleaning without damaging delicate leaves.

Efficient Drying: The air-drying equipment effectively removes surface water droplets, reducing the risk of spoilage and preparing vegetables for packaging or further processing.

Automation and Efficiency: The line is designed for high automation, minimizing manual labor and increasing throughput.

Versatility: Suitable for a variety of leafy vegetables, making it a flexible solution for different types of produce.

Application Fields:

Vegetable Processing Plants: Ideal for processing plants that handle large volumes of leafy vegetables, ensuring they are clean and dry for further processing or packaging.

Vegetable Processing Plants: Ideal for processing plants that handle large volumes of leafy vegetables, ensuring they are clean and dry for further processing or packaging.

Central Kitchens: Suitable for central kitchens that require clean and dry vegetables for meal preparation, enhancing hygiene and quality.

Food Service Industry: Beneficial for large-scale food service operations, such as catering companies, hotels, and restaurants, where high volumes of clean and dry vegetables are needed.

Packaged Vegetable Industry: Perfect for companies producing packaged, ready-to-use vegetable products, ensuring they meet hygiene and quality standards.

Agricultural Cooperatives: Useful for cooperatives that process and supply clean vegetables to markets or directly to consumers.

Usage Considerations

Regular Maintenance: Ensure all components, including the water filtration system and air-drying equipment, are regularly maintained and cleaned to prevent blockages and ensure efficient operation.

Proper Training: Operators should be trained to handle the equipment correctly, ensuring safety and optimal performance.

Consistent Monitoring: Regularly monitor the water quality and filtration system to ensure the water remains clean and effective for washing.

Safety Protocols: Follow all safety protocols, including wearing protective gear and ensuring that all safety guards are in place during operation.

Adjustable Settings: Utilize adjustable settings on the conveyor speed and air-drying intensity to accommodate different types and volumes of vegetables.

Energy and Water Efficiency: Optimize the use of energy and water to minimize costs and environmental impact, ensuring sustainable operation.

Quality Control: Implement quality control measures to ensure vegetables are thoroughly cleaned and dried, meeting the required standards for cleanliness and moisture levels.

The Vegetable Washing and Drying Line is an advanced, automated solution designed for the efficient and thorough cleaning and drying of leafy vegetables. Its comprehensive features and high level of automation make it an ideal choice for various applications in the food processing industry.