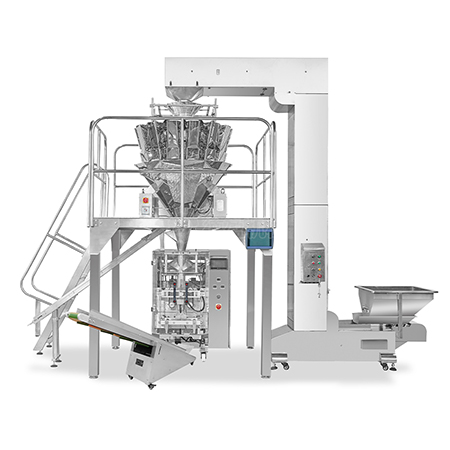

A Vertical Packaging Machine, also known as a vertical form-fill-seal (VFFS) machine, is a versatile piece of equipment used in the packaging industry for the efficient and automated packaging of a wide range of products. This type of packaging machine is capable of forming, filling, and sealing bags or pouches in a vertical orientation.

Here's a description of a Vertical Packaging Machine:

Vertical Forming and Material Unwinding:

The process begins with a roll of packaging material, usually a flexible film or plastic. The machine unwinds the material, and it is vertically formed into a tube-like shape with a vertical seal at one side. The continuous web of material is pulled downwards for the next steps.

Filling the Product:

Once the vertical tube is formed, the product to be packaged is measured and dispensed into the open end of the tube. The volume of product is controlled and measured precisely to ensure consistent packaging.

Sealing the Top:

After filling, the top end of the tube is sealed horizontally, creating a sealed pouch. This seal is often achieved by heat sealing, although other sealing methods like ultrasonic or cold sealing can also be used, depending on the type of packaging material.

Cutting and Separation:

Once the top is sealed, the filled pouch is separated from the continuous material web. A cutting mechanism, such as a rotary knife or heated blade, ensures that each pouch is cut free from the material roll.

Final Sealing and Embossing:

The bottom of the pouch, which is still open, undergoes a final horizontal sealing operation. This seals the bottom of the pouch and ensures that the product is securely enclosed. Some machines also include an embossing or coding feature to print product information, expiration dates, or branding on the packaging.

Packaging Materials:

Vertical Packaging Machines are compatible with a variety of packaging materials, including polyethylene, polypropylene, laminates, and more. The choice of material depends on the product being packaged and specific packaging requirements.

In summary, a Vertical Packaging Machine is a highly efficient and versatile piece of equipment that streamlines the packaging process by forming, filling, and sealing bags or pouches in a vertical orientation. Its adaptability, speed, and precision make it an essential tool for various industries looking to efficiently package their products.

The machine begins by unwinding a roll of flexible packaging material. The material is then formed into a tube, filled with the product, and sealed both vertically and horizontally to create individual pouches. This entire process is automated and ensures consistent and precise packaging.

Vertical Packaging Machines are versatile and can handle a wide array of products, including snacks, grains, powders, liquids, frozen foods, hardware items, pharmaceuticals, and more. These machines can adapt to various packaging needs, making them suitable for different industries.

Using a Vertical Packaging Machine offers several advantages, such as high-speed packaging, precise dosing, minimal material wastage, versatility in pouch styles, easy integration into production lines, and the ability to handle different packaging materials. These advantages contribute to increased efficiency and reduced production costs.

Vertical Packaging Machines achieve precision in filling through different dosing systems. Auger fillers, volumetric fillers, and multi-head weighers are commonly used. These systems accurately measure the product, ensuring that each pouch contains the specified quantity, regardless of the product's texture or consistency.

Vertical Packaging Machines can produce various packaging styles, including pillow bags, gusseted bags, quad seal bags, and doy bags. Pillow bags are flat and widely used, while gusseted bags have expanded sides, providing more space. Quad seal bags have four flat sides, offering stability, and doy bags are stand-up pouches with a bottom gusset, providing an appealing display.

Vertical Packaging Machines contribute to sustainability by minimizing material wastage. These machines optimize material usage, ensuring that packaging material is used efficiently. Additionally, the reduction in wasted product due to precise filling leads to less food waste, aligning with sustainable practices.

Vertical Packaging Machines play a vital role in automation by seamlessly integrating into automated production lines. Their ability to form, fill, and seal pouches autonomously ensures continuous and efficient packaging operations. Automation improves productivity, reduces labor costs, and enhances overall manufacturing efficiency.

Yes, Vertical Packaging Machines can handle sensitive and fragile products with care. Specialized dosing systems and gentle handling mechanisms prevent damage to delicate items during the filling and packaging process. This capability allows the machines to package items like cookies, chips, and other fragile goods without compromising product integrity.

Vertical Packaging Machines contribute to food safety by creating a sealed and hygienic packaging environment. The sealed pouches protect the contents from contaminants, ensuring that the products reach consumers in safe and pristine condition. Vacuum options can further enhance food safety by removing air from the pouch, extending shelf life and preventing spoilage.

When selecting a Vertical Packaging Machine, businesses should consider factors such as production speed, pouch styles, dosing accuracy, ease of operation, maintenance requirements, and the compatibility of the machine with specific packaging materials. Evaluating these factors helps businesses choose a machine that meets their unique packaging needs.

Vertical Packaging Machines enhance branding and product visibility through customizable pouch designs. The machines can create pouches with vibrant graphics, logos, and product information, enhancing shelf appeal. Attractive and informative packaging not only attracts consumers but also communicates brand identity effectively.

Modern Vertical Packaging Machines incorporate advanced technologies such as touchscreen interfaces, smart sensors, automatic adjustment features, and remote monitoring capabilities. These innovations improve user experience, increase operational efficiency, and allow for real-time monitoring of production processes.

| Technical Parameters | |

| model | DY-VP420 |

| membrane thickness | 0.04~0.12mm |

| speed range | 5~90 packs/min |

| Air consumption | 0.8Mps, 0.5m³/min |

| Film width range | 120~420mm |

| Bag making type | pillow bag |

| Bag size | Width 60~200mm, length 50~300mm |

Dimensions | 4423*2647*3690mm |

| using electric | Single phase 220v±5% 50~60HZ 2.2~3.9KW |

| Packaging film materials | POPP/CPP, POPP/VMCPP, CPP/PE, Ect |

| Alarm status | ①No bag or material alarm and shutdown ②Equipment overload alarm ③Low temperature and no ribbon alarm |