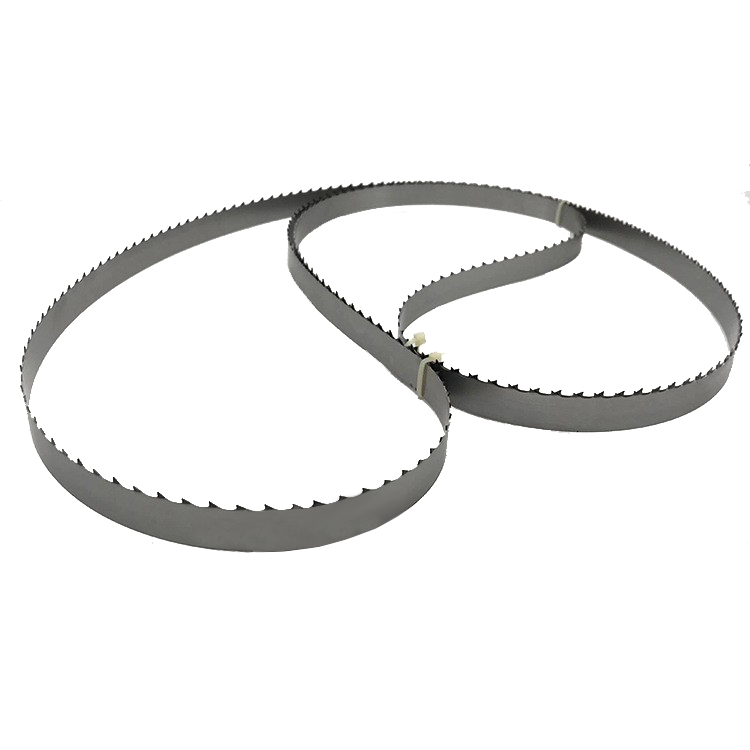

Bone blades are high-performance tools designed specifically for cutting bones, cartilage, and some hard tissues, and are widely used in the food processing industry. Installed on a dedicated bone saw or electric bone saw, it can efficiently and accurately cut various types of bones to meet cutting work in different environments and needs. The design of bone blades usually takes into account their compressive strength, wear resistance, and sharpness to ensure long-lasting performance in high-intensity cutting work.

| Technical Parameters: | |

| Product length: | 1140-6000MM (full specifications can be customized) |

| Product width: | 13/19/27/34/41/54/67MM |

| Product hickness | 0.6/0.9/1.1/1.3/1.6MM |

Function

Cutting bones: The most direct function of bone blades is to cut animal bones, especially in the food processing industry, such as meat processing plants, slaughterhouses, etc. It can quickly cut bones into the required size for further processing or packaging.

Cutting cartilage and hard tissues: In addition to bones, bone blades can also be used to cut cartilage or other hard tissues, such as joints and joints of animals such as pigs, cattle, and sheep. Its sharpness and strength enable it to cope with the cutting needs of these hard tissues.

Medical use: In the field of medical surgery, bone blades are often used in surgical operations, especially in fracture repair, plastic surgery, and orthopedic surgery. They can accurately cut bone tissue and help doctors perform accurate surgical operations.

Improve production efficiency: In food processing plants, especially in large-scale processing plants, bone blades can automatically and efficiently complete cutting work, reduce manual operations, improve production efficiency, and reduce labor intensity.

Features

High-strength materials: Bone blades are usually made of high-strength alloy steel, stainless steel or ceramic materials, which can resist wear during long-term use and have strong compressive resistance. Due to the high hardness of bones, the material of the blade must have high wear resistance and impact resistance.

Sharp blade design: The blade design of bone blades is usually very sharp, and the use of precision blade cutting technology can efficiently and cleanly cut bones and other hard tissues. The high-precision edge design ensures a smooth cutting surface without excessive debris.

Corrosion resistance: Since bone blades are often used in contact with food, especially in a humid environment, they are usually made of stainless steel or anti-corrosion alloy materials to ensure the durability and hygiene of the blades and prevent the blades from rusting or deteriorating during use.

Adapt to different equipment: Bone blades are designed with a variety of specifications and sizes, which can adapt to different brands and types of bone saws, cutting machines, surgical tools and other equipment. Whether it is manual or automated, bone blades provide stable cutting results.

Various shapes and sizes: Bone blades are designed in different shapes and sizes according to specific needs, such as straight blades, curved blades, circular blades, etc. These different designs can meet different types of cutting tasks and adapt to different cutting angles and ranges.

Advantages

Efficiency: The design of bone blades enables them to cut bones and other hard tissues quickly and efficiently, which can greatly improve work efficiency and reduce the time required for cutting in large meat processing plants or operating rooms.

Precision: Thanks to the high-precision production process, bone blades can provide very precise cutting results, reducing debris and irregular cutting surfaces during cutting. This is essential for cleanliness and precision requirements during meat processing or surgery.

Durability: Due to the use of high-strength, corrosion-resistant materials, bone blades can remain sharp during long-term use, reducing the frequency of replacement, thereby reducing the cost of long-term use.

Versatility: Bone blades are not only suitable for various meat cutting, but also for bone cutting in medical surgery and even in some industrial applications. Its versatility makes it widely adaptable and can play a role in multiple industries and fields.

Reduce labor costs: Automated bone blades can be used with mechanical equipment for batch cutting, reducing manual operations, reducing labor costs, and improving productivity.

Safety: Bone blades are designed with safety in mind, and are usually equipped with protective devices or anti-slip designs to avoid unnecessary injuries during cutting. For medical surgery, precise blade design can also ensure the accuracy of cutting during surgery and reduce the risk of accidental injury.

Application areas

Food processing industry: The most widely used application area for bone blades is the food processing industry, especially meat processing plants, slaughterhouses, etc. It can efficiently cut bones, cartilage and meat tissue to meet the needs of large-scale production.

Medical industry: Bone blades are widely used in surgical operations, especially orthopedic and plastic surgery. It can accurately cut bones and provide doctors with precise surgical incisions to help quickly repair fractures or make bone adjustments.

Operating room and veterinary: In veterinary surgery, bone blades also play a vital role in dealing with bone problems in pets or livestock. It can help doctors perform surgery quickly and safely, reducing the pain of sick animals.

Industrial application: In some industrial fields, bone blades can also be used to cut some hard materials, such as ceramics, metals, etc. Cutting tasks in these fields usually require high-strength blades to complete.

Precautions

Regular cleaning: Bone blades should be thoroughly cleaned after each use, especially in the field of food processing, where cleaning is essential. Meat residue or other food residues remaining on the surface of the blade not only affect the cutting quality, but may also cause food contamination.

Avoid collision and falling: Bone blades are high-precision cutting tools. Avoid collision or falling of hard objects to avoid damage or deformation of the blade, affecting the cutting effect and safety.

Check the blade regularly: The blade of the bone blade needs to be checked regularly to ensure that it remains sharp. Blade wear or blunting will cause uneven cutting, increase cutting time and difficulty. For blunt blades, they should be sharpened or replaced in time.

Storage environment: The blade should be stored in a dry and ventilated place after use, avoiding contact with moisture or humid environment to prevent rust. For stainless steel blades, anti-rust oil should also be applied regularly to increase their service life.

Regular replacement: Although high-quality bone blades are very durable, the performance of the blades will gradually decrease with the increase in the number of uses. Regularly replace the blades to ensure cutting quality and work efficiency.

Safe operation: When using bone blades, strictly follow the operating manual of the equipment to ensure the safety of personnel. Especially in the medical and food processing fields, special attention should be paid to safety regulations during operation.

As a high-performance cutting tool, bone blades play an important role in food processing, medical surgery and industrial fields with their powerful cutting ability, high-precision design and durable materials. It not only improves production efficiency, but also ensures cutting accuracy and quality, meeting the cutting needs of different industries. During use, reasonable maintenance and care can extend its service life and ensure safe and efficient completion of cutting tasks.